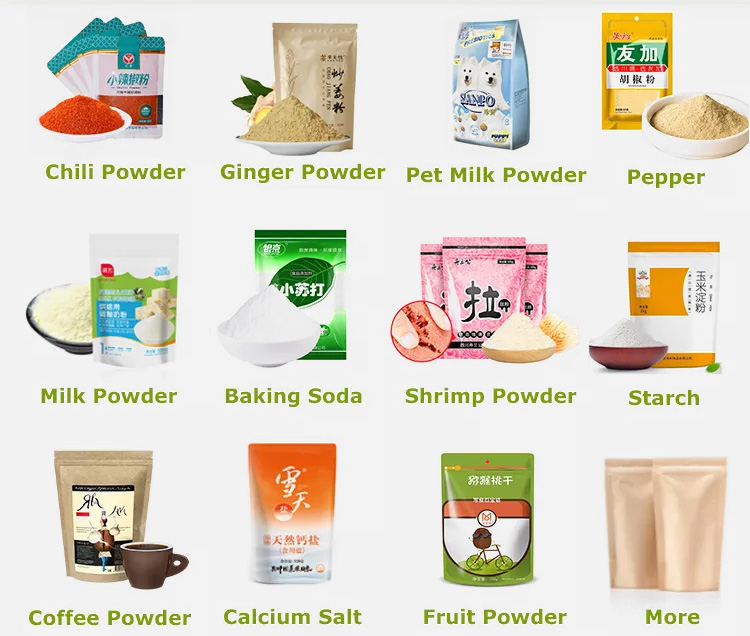

Powder doypack machine

Model | 250R |

Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

Filling range | ≤1000kg |

Bag size : | Bag Width : 140-245mm; Bag height : ≤450mm |

Packing speed | 10-60bag/min speed is determined by the product filling quantity |

Average | ≤ ±1 |

Total power | 2.5KW |

Dimensions | 1900mm X 1570mm X 1700mm |

Work flow | giving bag→coding →opening →filling 1 →filling 2 → auxiliary→ exhaust→ heat sealing→ .forming and output product |

Station 1 : Pouch feeding

Feed many pouches or bags in the bag magazine, our main bag magazine can be adjusted by pouch sizes, you can feed pouches very easily when

it feeding, there are a mechanical arm with Servo Motor will take bag up and then transmit it to the mechanical gripper on the clamp turntable.

Station 2 : Date Printing or Reserved

According to the actual production needs of the customer, this workstation can be equipped with coding machine to print the packaging date and batch number

Station 3 : Pouch Opening, zipper opening device

At the same time as the opening suction cup sucks open the bag opening, the upper spray pipe sprays air into the packaging bag. The bag is then opened and

transported to the next workstation by the bag spreading plate, and the presence of the packaging bag or whether the bag opening is detected is completed; If there

is no packaging bag or the bag opening is not opened, the filling station will not fill the material and will not enter the vacuum chamber.

Station 4 : Filling material workstation (Filling)

Insert the filling material hopper into the packaging bag, and the bag spreading piece is completed and returned to the original workstation; Fill the material into the

packaging bag. (Depending on the material, there may be differences in the filling system configuration of this workstation) Complete the fully automatic or semi-automatic

placement and filling of materials.

Station 5: Material Pocking or liquid filling station (Filling)

Depending on the different conditions of the materials, different devices can be selected and installed at this workstation to perform secondary treatment on the

materials inside the packaging bags

Station 6 : Pouch Straightenning, pouch flattening

After cleaning, the packaging bag is straightened for the first time to avoid wrinkles at the bag mouthand ensure a smooth and beautiful sealing of the packaging bag.

Station 7 : Preheating and sealing station(Heating)

he packaging bag filled with materials enters this workstation

Machine Features

1. The powder and measuring packaging system consists of a rotary packaging machine, a screw scale, and a screw elevator

2. Perfect quality, ensuring high-speed and stable production

3. Use high-quality accessories to maintain the long-lasting stability of the machine

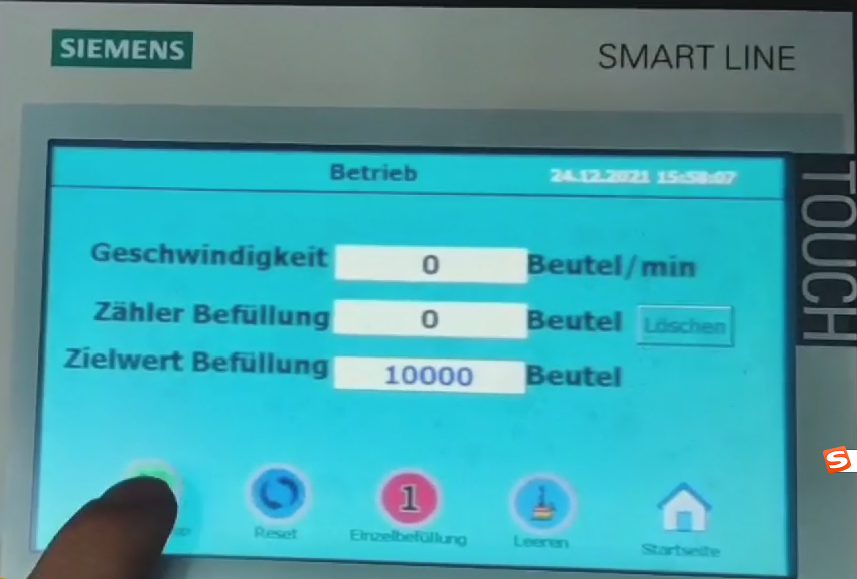

4. Adopting a color touch screen display, simple operation

5. Innovatively solve packaging problems for various products at a reasonable cost

6. This machine uses pre made bags with perfect patterns, good sealing quality, and low packaging wear and tear